Introduction

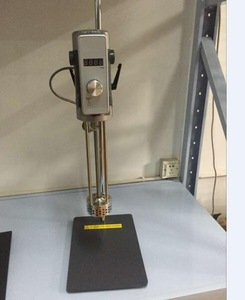

High shearing-rate dispersing and emulsifying machine has been widely used since 1980’s in developed countries such as USA and Western European countries. It also has been put into use in Chinese rapidly in recent years. This machine has several functions like mixing, emulsifying, smashing, homogenizing and dissolving in single equipment, so it can replace the traditional sand-grinding machine, ball mill, colloid mill and three-roller mill. It has wide applications in painting, printing ink, food, beverage, printing and dyeing, pharmacy, rubber, essence, cosmetic and daily chemicals. This machine is very fit for painting manufacturing for its overcoming the shortages of huge invest, complicate process procedure and inferior quality and it can shorten process recycle greatly and is easy for cleaning.

Working principle:

High shearing-rate dispersing and emulsifying machine is consisted of a group or several groups rotors and stators, which are rotating at a very high speed during working. The high-speed rotating rotor sucks material into the rotor’s cavity very quickly, makes it influenced by shearing and dispersing effect. The material is forced to flow through tiny gap between stator and rotor and throw out of holes or slots in the stator. The huge shearing force generated by speed gradient in gap between static stator and high-speed rotating rotor strengthens the mass transferring intensity, improves dissolving ability of single material and macro-molecule material, makes the pumped media flow in turbulent state and promotes the distributing state for both solid and liquid particles. The three-dimension local speed fluctuation varying according to time phase leads to high frequency pressure fluctuation. Several smashing mechanisms work together and can disperse the media to very fine granularity. While the new material entering the rotor cavity, part of the thrown out material will change flow direction when it bounces on container’s wall and reenter the rotor cavity to enduring shearing effect again. Thus, the material will be thoroughly refined, homogenized and dispersed and the best shearing effect is reached.

Models:

| Model | Power(kw) | Rotation (r/min) | Dealing Capacity (L) |

| HIJ101 | 1.5 | 2900 | 15-100 |

| HIJ105 | 4 | 2900 | 100-200 |

| HIJ110 | 7.5 | 2900 | 150-400 |

| HIJ115 | 11 | 2900 | 200-600 |

| HIJ125 | 18.5/22 | 2900 | 300-1000 |

| HIJ140 | 30 | 2900 | 500-3000 |

Đánh giá

Hiện tại chưa có đánh giá nào cho sản phẩm này.